- Precision system: High-performance servo + screw rod + guide rail closed-loop control

- Visual positioning (optional): For accurate hole drilling

- Clean processing: Vacuum and circular air-blowing system ensures drilling effect and dust-free environment

- Stable control: High-precision water-cooled galvanometer + telecentric lens minimizes taper

- Custom hole types: Supports tapered, stepped, chamfered, and irregular-shaped holes

- Narrow pulse laser: Small perforation edges, fast cutting

- Software: Easy-to-use drilling software meets various application needs

| Equipment name | Glass Laser Drilling Machine |

| Laser type | Green pulsed laser / Infrared nanosecond laser |

| Laser power | 60W / 100W / 140W / 200W / 250W |

| Laser wavelength | 532nm / 1064nm |

| Pulse duration | 7ns@100kHz / 8ns@100kHz |

| Impulse frequency | 50–500kHz / 1–4000kHz |

| Cooling method | Water cooling |

| Drilling method | 2D or 3D scan drilling |

| Drilling head | High-precision galvanometer + quartz focusing lens |

| Drilling area | 1mm – 100mm |

| Drilling speed | 0–7000 mm/s (adjustable) |

| Glass thickness | 0.5mm – 20mm |

| Perforated edge range | 30–200μm / 150–300μm |

| Processing area | Single-head 70–100mm or customized |

| Drive motor | Linear motor / servo motor |

| Positioning accuracy | ±10–50μm |

| Software performance | Round, square, stepped, tapered, irregular holes |

| Dust removal system | Follow-up dust collection |

| Power supply | AC220V ±5%,<3KW |

| Machine size | Depends on processing range (customized) |

| Weight | 200KG – 1000KG |

| Ground bearing | >500kg/m² |

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

1. We offer reliable international payment options:

Letter of Credit (L/C): Ideal for high-value orders, ensuring security for both buyer and seller.

Telegraphic Transfer (T/T): Common method — 30% deposit in advance, 70% balance before shipment.

PayPal / Western Union: Suitable for small parts or sample payments (not recommended for full-size machines).

2. Delivery Methods

Due to the size and weight of our glass laser equipment, we primarily ship via ocean freight:

Sea Freight (Container Shipping): The most suitable and economical solution for all equipment models.

Air Freight: Not available for most full-size machines. Can be arranged for small accessories or demo units upon request.

3. Delivery Time

Production Lead Time: Usually 30–50 working days after receiving the deposit.

Shipping Time: Delivery varies by destination. Typically 15–40 days by sea, depending on the port location.

4. Shipping Costs

Shipping costs depend on the destination port, machine dimensions, and total weight.

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

1. Warranty Period:

Laser Machine: 18 months

Within 12 months, free replacement of parts, including the laser device.

For failures caused by non-human reasons, our company will send new accessories to customers for free, including the laser source.

Customers will need to send back faulty parts (laser source) first.

For other parts, there is no need to return them.

From 12 to 18 months, the customer will bear the laser cost and postage.

Both parties will share the postage cost for the return of the laser device.

The customer will send the faulty laser to our bonded warehouses in Jinan or Shenzhen, China. The purpose of this is to avoid complex customs procedures.

After 18 months, the laser source will cost, and the customer will need to buy the parts and cover the postage costs.

2. Laser Charging Instructions

| Time | Laser | Remark |

| Within 12 months | Free replacement | Both parties pay the postal fee (If received within one month, customer bears no cost) |

| 12–18 months (During the warranty period) | Laser source cost × 0.2 | Both pay postage Send to bonded warehouse in China (Jinan/Shenzhen) |

| After 18 months (Out of warranty) | Laser source cost × 1.2 | Buy directly, customer pays postage |

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

A: The standard platform size is 600mm × 600mm, referring to the maximum X/Y travel range of the laser head. Larger sizes can be customized based on requirements.

Q2: What is the range of hole diameters it can drill?

A: The machine supports drilling diameters from 1mm to 100mm, suitable for through holes, blind holes, round, square, and simple polygonal shapes.

Q3: What glass thickness can it process?

A: The machine supports thicknesses from 0.1mm to 19mm, but the most common range in actual production is 2mm to 8mm flat glass.

Q4: What special hole shapes can it drill?

A: It supports step holes, tapered (trumpet-shaped) holes, and other irregular holes, which can be processed automatically via imported CAD drawings.

Q5: Are there any shape limitations for the holes?

A: Yes. To avoid stress concentration and cracking, sharp corners should be avoided. Rounded or circular designs are recommended for best results.

Q6: What types of glass are suitable for drilling?

A: The glass must be light-transmitting. Clear, white, and ultra-clear glass are suitable, while dark or opaque glass cannot be processed.

Q7: Will the hole edges chip during drilling?

A: Chipping is minimal.

Infrared laser: approx. 200–300μm edge chipping

Green laser: finer control, approx. 100μm, with smooth edges

Q8: Can it drill tempered glass?

A: No. All holes must be drilled before tempering. Drilling after tempering will cause the glass to shatter.

Q9: How are drilling time and power parameters set?

A: Drilling time and laser power depend on glass thickness, hole diameter, and material type. A detailed parameter chart is available for reference.

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

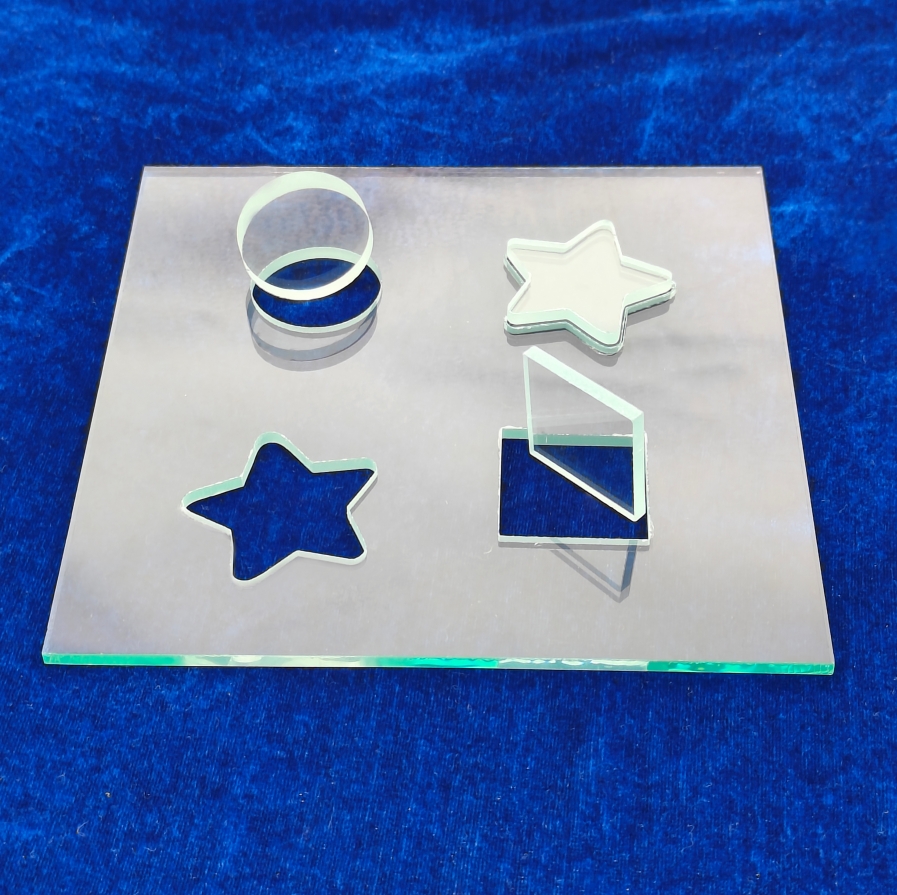

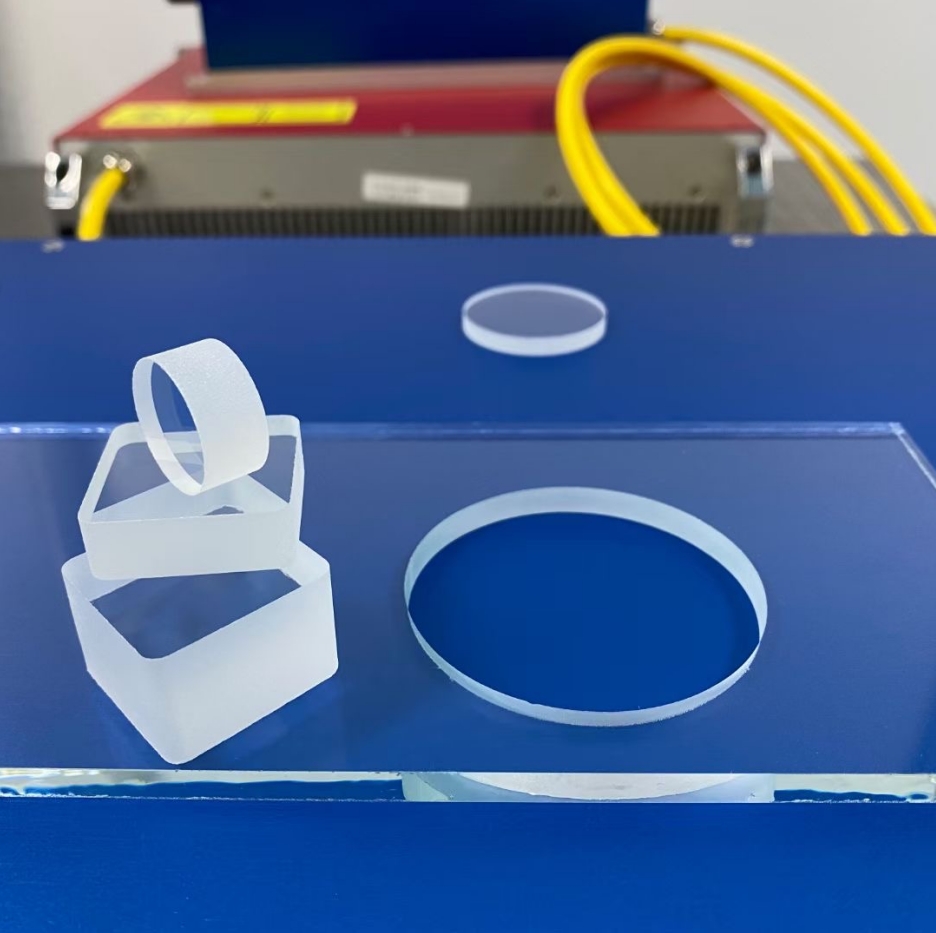

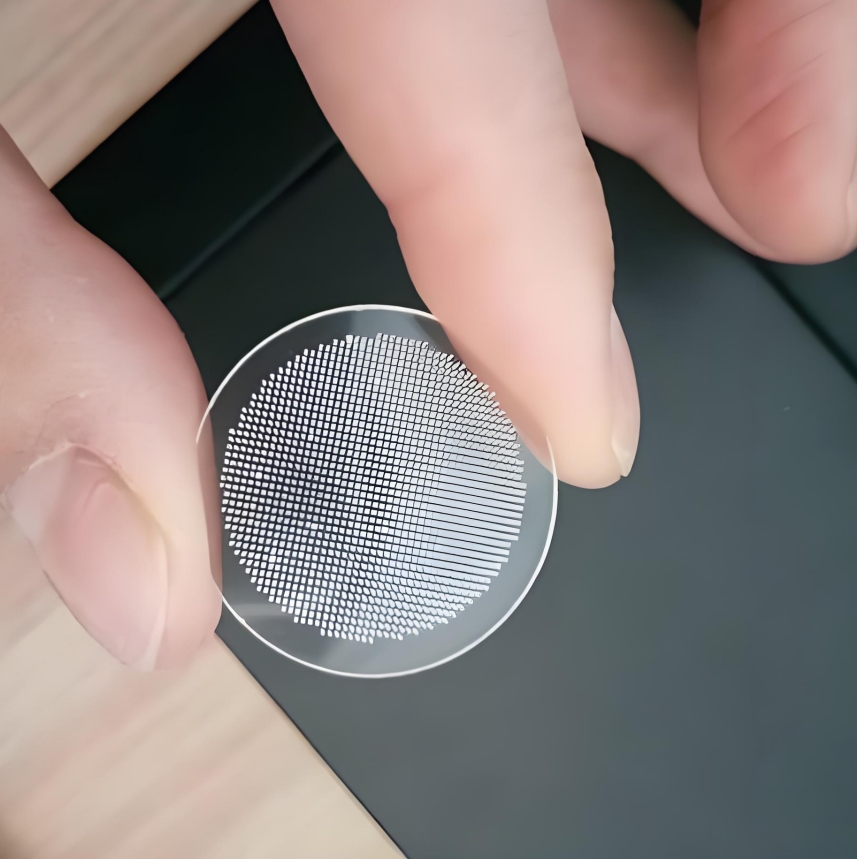

Sample Display