Description

- Non-contact processing, safe and efficient.

- No consumables, environmental protection, clean, energy-saving.

- Multi-head laser structure can be used to greatly improve the efficiency of film removal.

- The single platform structure and automated production line structure can be customized according to customer needs.

- Good film removal effect, no damage to the glass substrate.

- The editing of film removal trajectories and patterns is simple. You can start the film removal process right after the editing is done. It is suitable for film removal of various complex patterns and large-format areas.

| Structural type | Vertical gantry / Gantry paving / automatic connection structure (single head or multiple heads) |

| Platform size | 1300*2500mm / customized on demand |

| Effective processing size | 1300*2500mm / customized on demand |

| Servo drive system | With the bus absolute value system, which enables the servo motor to record the precise position even in case of unexpected power failure or shutdown. |

| Drive system | High precision double track and screw guide rail / high precision linear motor |

| Laser output power | 120W / 200W / 300W / 500W |

| Laser type | Pulsed infrared laser / pulsed green laser |

| Processing range of lens | 70*70mm / 100*100mm (optional) |

| Cooling system | High-precision constant-temperature cooling machine |

| Laser Q-switching frequency | 1-4000kHz |

| Total power of the machine | 3.5–6.5KW |

| Minimum line width | 0.01mm |

| Repeat positioning accuracy | ±0.05mm |

| Working power supply | AC 220V / 50Hz (customized on demand) |

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

1. We offer reliable international payment options:

- Letter of Credit (L/C): Ideal for high-value orders, ensuring security for both buyer and seller.

- Telegraphic Transfer (T/T): Common method — 30% deposit in advance, 70% balance before shipment.

- PayPal / Western Union: Suitable for small parts or sample payments (not recommended for full-size machines).

2. Delivery Methods

Due to the size and weight of our glass laser equipment, we primarily ship via ocean freight:

- Sea Freight (Container Shipping): The most suitable and economical solution for all equipment models.

- Air Freight: Not available for most full-size machines. Can be arranged for small accessories or demo units upon request.

3. Delivery Time

- Production Lead Time: Usually 30–50 working days after receiving the deposit.

- Shipping Time: Delivery varies by destination. Typically 15–40 days by sea, depending on the port location.

4. Shipping Costs

Shipping costs depend on the destination port, machine dimensions, and total weight.

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

1. Warranty Period:

Laser Machine: 18 months

Within 12 months, free replacement of parts, including the laser device.

For failures caused by non-human reasons, our company will send new accessories to customers for free, including the laser source.

Customers will need to send back faulty parts (laser source) first.

For other parts, there is no need to return them.

From 12 to 18 months, the customer will bear the laser cost and postage.

Both parties will share the postage cost for the return of the laser device.

The customer will send the faulty laser to our bonded warehouses in Jinan or Shenzhen, China. The purpose of this is to avoid complex customs procedures.

After 18 months, the laser source will cost, and the customer will need to buy the parts and cover the postage costs.

2. Laser Charging Instructions

| Time | Laser | Remark |

| Within 12 months | Free replacement | Both parties pay the postal fee (If received within one month, customer bears no cost) |

| 12–18 months (During the warranty period) | Laser source cost × 0.2 | Both pay postage Send to bonded warehouse in China (Jinan/Shenzhen) |

| After 18 months (Out of warranty) | Laser source cost × 1.2 | Buy directly, customer pays postage |

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

Q1: What types of films can this machine remove?

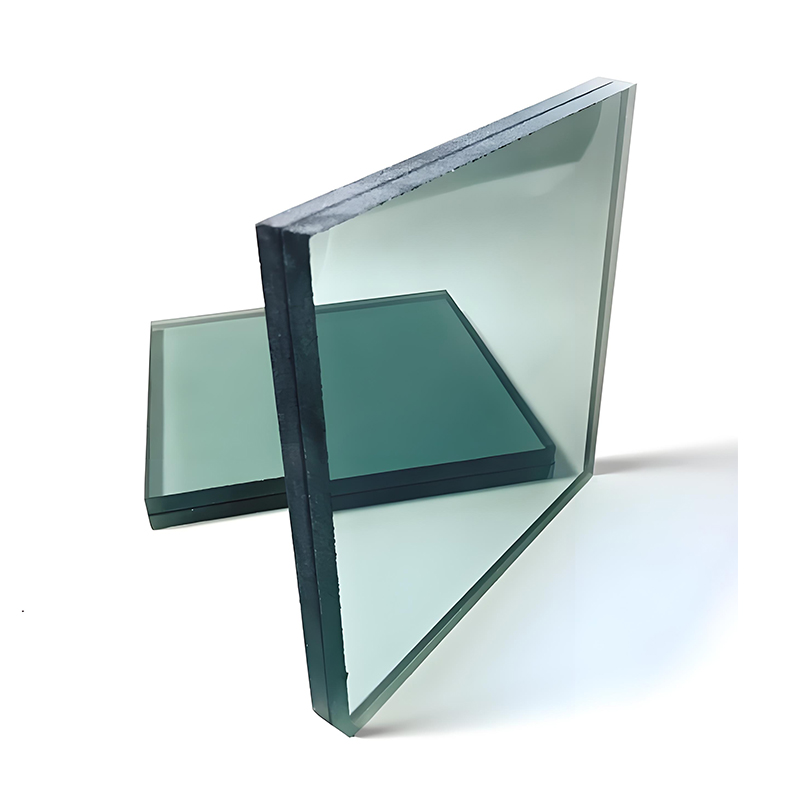

A: It is designed to remove ITO coatings, heating films, silver mirror reflective layers, and other functional coatings on coated glass. It also supports film removal on photovoltaic (PV) glass surfaces. Common applications include smart mirrors, touch panels, decorative glass, and solar glass modules.

Q2: Will the laser damage the glass surface during film removal?

A: No. The laser is precisely focused on the film layer and does not affect the base glass material or its light transmittance.

Q3: Can the film removal width be customized?

A: Yes. The removal width can be set freely (typically 1–50mm) and also supports scanned path removal based on imported drawings.

Q4: Is the film removal result visible to the naked eye?

A: Yes. The removed area has clean edges, no residue, and sharp contrast, making it suitable for printing, plating, or further laser marking.

Q5: What other functions does the machine support?

A: In addition to film removal, it also supports:

- Laser sandblasting

- Laser marking

- Laser drilling

It is a multifunctional system, suitable for various glass processing tasks.

Q6: What industries or products is this machine suitable for?

A: It is widely used in:

- Smart mirrors (bathroom, LED, and touch mirrors)

- Decorative glass (logo removal, design windows)

- Photovoltaic glass (edge film removal for solar cells)

- Home appliance glass (heating film cleaning)

- Lighting glass (combined film removal, sandblasting, and drilling)

Q7: How many people are needed to operate the machine?

A: Only one operator is needed. The system is easy to use and fully automated from loading to processing.

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

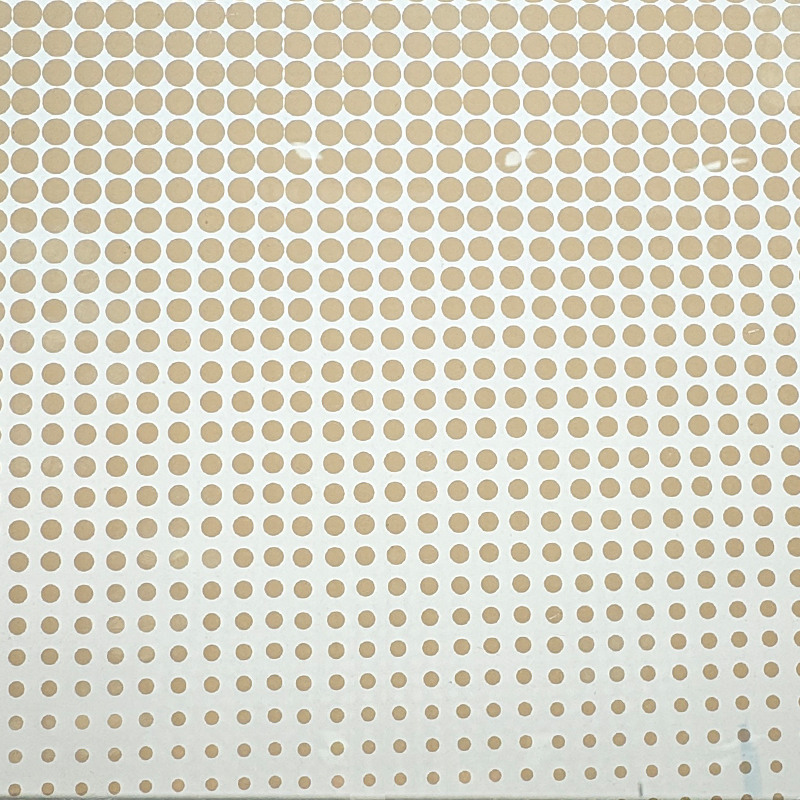

Sample Display