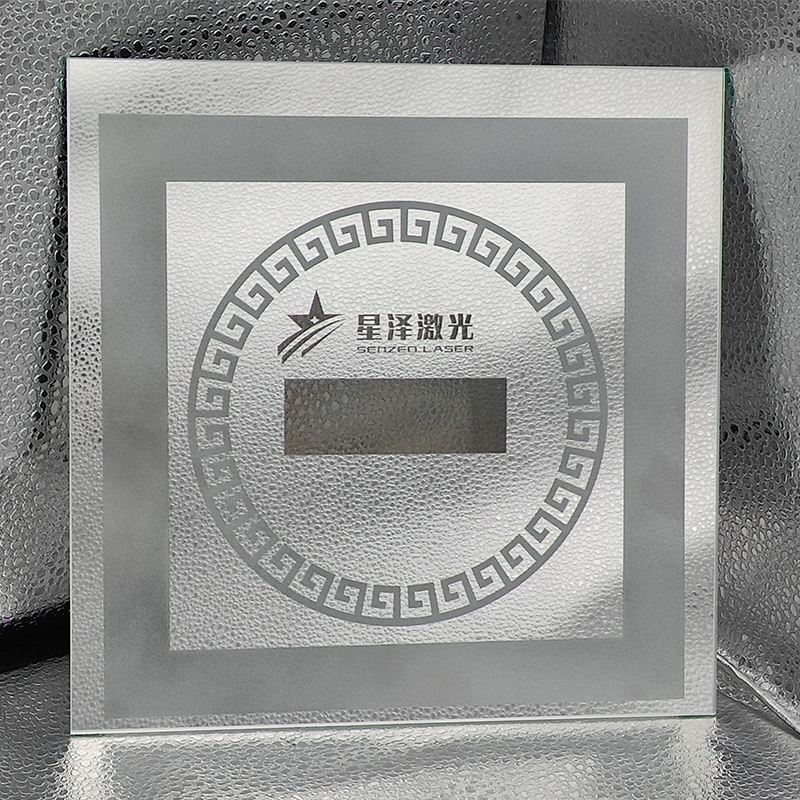

- Applied to: Film removal, sandblasting, drilling and marking of clear glass and silver-plated mirrors

- One-step processing: Sandblasting, hole drilling and marking can be completed in one forming process

- Air-blowing system: Annular air-blowing system ensures fine drilling results

- Processing size: 600–2500mm (customizable)

- Efficiency: Greatly improves efficiency over traditional methods, saves labor

- Operation: Easy to operate, high efficiency, low energy cost, and eco-friendly

- Vacuum option: High negative pressure vacuum device (optional) ensures clean dust handling

- Laser source: Imported pump laser for stable and efficient performance

| Equipment model | CZ-SS01-1325-A/B / CZ-XG01-1325-A/B |

| Structural type | Gantry paving / gantry side hanging (optional) |

| Machine size | 2100 × 3800 × 1300 mm (or customized) |

| Platform size | 1300 × 2500 mm (or customized) |

| Effective processing size | 1200 × 2400 mm (or customized) |

| Laser output power | 140W / 200W / 250W |

| Laser type | Narrow pulse width infrared laser |

| Lens range | 70 × 70 mm / 100 × 100 mm (optional) |

| Cooling system | Water cooling |

| Q-switching frequency | 1–4000 kHz |

| Total power | 3500 W |

| Minimum line width | 0.01 mm |

| Repeat accuracy | ±0.05 mm |

| Power supply | AC 220V / 50Hz (customized on demand) |

| Operating environment | Windows 10 |

- One machine supports multi-function: sandblasting, drilling, marking, film removal on flat or large-size glass

- Seamless sandblasting function: handles lines, strips, rings, squares, logos and irregular shapes

- Drilling function: supports round holes, square holes and irregular holes (diameter 60–100mm)

- Z-axis servo autofocus: no manual adjustment needed; fast and precise

- Automatic dust collection (optional): continuous negative pressure vacuum cleaning for eco-friendly dust removal

- Power-off protection: remembers position and safe state for restart after outage

- Online upgrade & maintenance: system can be updated and adjusted remotely

Offline simulation: system can run on external computer without occupying production machine

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

1. We offer reliable international payment options:

Letter of Credit (L/C): Ideal for high-value orders, ensuring security for both buyer and seller.

Telegraphic Transfer (T/T): Common method — 30% deposit in advance, 70% balance before shipment.

PayPal / Western Union: Suitable for small parts or sample payments (not recommended for full-size machines).

2. Delivery Methods

Due to the size and weight of our glass laser equipment, we primarily ship via ocean freight:

Sea Freight (Container Shipping): The most suitable and economical solution for all equipment models.

Air Freight: Not available for most full-size machines. Can be arranged for small accessories or demo units upon request.

3. Delivery Time

Production Lead Time: Usually 30–50 working days after receiving the deposit.

Shipping Time: Delivery varies by destination. Typically 15–40 days by sea, depending on the port location.

4. Shipping Costs

Shipping costs depend on the destination port, machine dimensions, and total weight.

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

1. Warranty Period:

Laser Machine: 18 months

Within 12 months, free replacement of parts, including the laser device.

For failures caused by non-human reasons, our company will send new accessories to customers for free, including the laser source.

Customers will need to send back faulty parts (laser source) first.

For other parts, there is no need to return them.

From 12 to 18 months, the customer will bear the laser cost and postage.

Both parties will share the postage cost for the return of the laser device.

The customer will send the faulty laser to our bonded warehouses in Jinan or Shenzhen, China. The purpose of this is to avoid complex customs procedures.

After 18 months, the laser source will cost, and the customer will need to buy the parts and cover the postage costs.

2. Laser Charging Instructions

| Time | Laser | Remark |

| Within 12 months | Free replacement | Both parties pay the postal fee (If received within one month, customer bears no cost) |

| 12–18 months (During the warranty period) | Laser source cost × 0.2 | Both pay postage Send to bonded warehouse in China (Jinan/Shenzhen) |

| After 18 months (Out of warranty) | Laser source cost × 1.2 | Buy directly, customer pays postage |

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

A: This machine supports the following laser functions:

– Sandblasting

– Marking

– Drilling

– Film removal

These functions can be used individually or combined based on production needs.

Q2: What are the main applications of this machine?

A: It is widely used for smart mirrors, decorative glass, lighting glass, and logo engraving. Suitable for both batch production and customized small orders.

Q3: Can this machine replace traditional sandblasting?

A: Yes. Laser sandblasting requires no consumables, produces no dust, and allows flexible pattern changes. It’s ideal for high-end mirror processing and artistic glass.

Q4: How deep can the sandblasting go?

A: The depth is adjustable. It supports light frosting, deep texture patterns, and embossed logo effects.

Q5: Is it suitable for large-size glass?

A: Yes. It supports glass or mirror sizes up to 1.2m × 2.4m, suitable for bathroom mirrors, glass doors, and large panels.

Q6: Can the sandblasting pattern be changed freely?

A: Yes. You can import any graphic or drawing file without changing templates. It enables fast switching and flexible customization.

Q7: Does it generate dust or require consumables?

A: No. The process is fully clean and dry — no abrasives, no dust, and no need for ventilation or dust collection systems.

Q8: Are there any restrictions on glass types?

A: No restrictions. Both regular glass and tempered glass can be processed by this machine.

Q9: How many people are required to operate the machine?

A: Only one operator is needed to complete the entire workflow. The system is easy to use and automation-ready.

- Contact information

Email: sales@xzlasers.com

WhatsApp: +8617702282583

Sample Display